Metal Forming

- Home

- Manufacturing

- Metal Forming

- Home

- Manufacturing

- Metal Forming

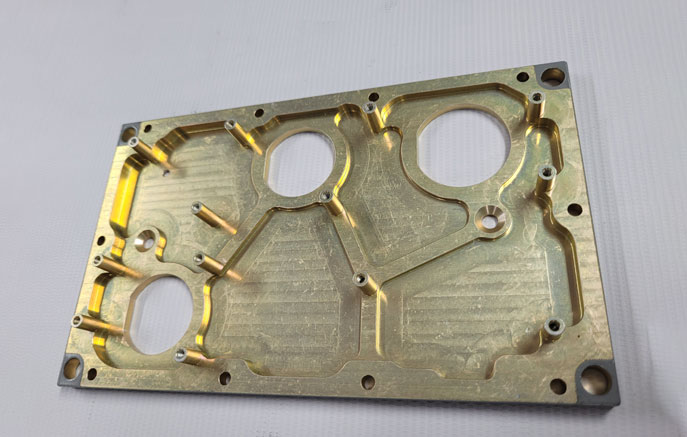

Precision Electronics Limited provides a one-stop shop for Metal Forming parts including Sheet Metal, Machined (Milled, Turned), Forged and Casted (High Pressure Die Casting, Investment Casting) parts. In-house prototyping and tooling facilities ensure quick turnaround for prototypes. PEL undertakes heat treatment, coating (chromate conversion, Zinc Coating, Passivation) and painting as per Automotive, Security and Aerospace (NADCAP) standards.

Casting

High Pressure Die Casting

Gravity Die Casting

Investment Casting

Sheet Metal

Laser Cutting

CNC Bending

Turret Punch

Machining

CNC Turning & Milling

Drill Tap Centers

Hot Forging

Our USPs

- CNC Milling

- VMC

- 3 Axis and 4 Axis

- High Speed Milling

- One Stop Shop for Metal Forming.

- Rapid Prototyping.

- Undertake High Mix Low Volume AND Large Volumes.

- 550 Turning and 150 Milling centres.

Secondary Process

Chromate Conversion (Alodine)

Zinc Plating - Yellow & Clear

Painting & Powder Coating

Chromate Conversion (Alodine)

Zinc Plating - Yellow & Clear

Painting & Powder Coating

Inspection & Testing

Our inspection processes are based on the AS9100D and IATF 16949 quality standards and products are manufactured compliant to industry/customer standards. The Machined parts are as DIN-ISO2768 Inspection using the latest inspection tools including but not limited to

- CMM : Coordinate Measuring Machine

- Surface Finish Tester Ra measuring machine

- Measurement Gauges for quick measurement during Bulk production

- Contour Tracer

- 3D Scanner – for complex & intricate parts

- Chemical Composition : NABL certified lab

- General Instruments: Surface Plate, Digi Matic Height Gauge, Vernier Callipers & Micrometre, Thread & Plug Gauges, Snap Gauges etc

Quality certifications